- #601c swf embroidery machine how to#

- #601c swf embroidery machine manual#

- #601c swf embroidery machine code#

- #601c swf embroidery machine free#

#601c swf embroidery machine how to#

20 MODEL CONDITION CAUSE HOW TO FIX REFERENCE 6. FABRIC IS BEING PULLED TOO STRONGLY WHILE SEWING. THE FABRIC MOVES WHILE THE NEEDLE IS PIERCING IT, OR THE NEEDLE ZIGZAGS WHILE IN FABRIC. SEE "NEEDLE DROP." P NEEDLE IS BENT OR WORN. REPAIR THE HOLE OR REPLACE THE NEEDLE PLATE. NEEDLE HOLE IN NEEDLE PLATE IS WORN OR BURRED. FOR USE APPROPRIATE NEEDLE AND THREAD FOR FABRIC IN USE. 20 MODEL CONDITION CAUSE HOW TO FIX REFERENCE 3. BOTH NEEDLE AND BOBBIN THREADS UNDER THE FOOT WHEN STARTING SEWING. THREAD ON BOTTOM SIDE MAKE SURE TO BRING OF FABRIC IS JAMMED UP. INCORRECT SEE P.18 MOVING FEED DOG HEIGHT "FEED DOG HEIGHT." 2. INAPPROPRIATE NEEDLE SEE P.16,17 TO HOOK CLEARANCE "CLEARANCE BETWEEN NEEDLE AND HOOK." 2. INAPPROPRIATE NEEDLE SEE P.20 TO HOOK TIMING "NEEDLE TIMING TO SHUTTLE." 8. INAPPROPRIATE NEEDLE SEE P.19 BAR HEIGHT "NEEDLE BAR HEIGHT." 7. SEWING ON STRETCH FABRIC USE A #11 BLUE TIP NEEDLE. USE THE RECOMMENDED SEWING NEEDLE AND THREAD. NEEDLE OR THREAD ARE INAPPROPRIATE FOR FABRIC BEING SEWN. 20 MODEL WHAT TO DO WHEN CONDITION CAUSE HOW TO FIX REFERENCE 1. NOTE: YOU MAY WANT TO CUT THE END OF THREAD WITH SHARP SCISSORS FOR EASIER NEEDLE THREADING. DRAW THREAD DOWN AGAIN AND SLIP IT INTO THE NEEDLE BAR THREAD GUIDE. FIRMLY DRAW THREAD UP AND THROUGH THE TAKE-UP LEVER FROM RIGHT TO LEFT. HOLDING THREAD TAUT WITH RIGHT HAND, DRAW THREAD DOWN INTO THE TENSION AREA AND THEN AROUND THE CHECK SPRING HOLDER. PLACE A SPOOL ON THE SPOOL PIN, WITH THREAD COMING OFF AS SHOWN. DOTTED LINES SHOW THE PLACES WHERE THE THREAD LOOPS AND THEN IS PULLED TIGHT. 20 MODEL PREPARE YOUR TOP THREAD FOR THREADING THE MACHINE, FOLLOW THE NUMBERS IN ORDER AS SHOWN ON THE ILLUSTRATION. CASE SHOULD LOCKINTO PLACE WHEN LATCHIS RELEASED.ĥ SEWING MACHINE DtV. HOLDING LATCH OPEN, POSITION 5 CASEINTO SHUTTLE AND RELEASE LATCH. PULL THREAD UNDER TENSION SPRING AND THROUGH THE OPENING AS SHOWN ABOVE. 2 PULL THREAD THROUGH SLIT OF CASE AS SHOWN. B PLACE BOBBIN IN BOBBIN CASE MAKING SURE THREAD FEEDS CLOCKWISE AND IS COMING FROM BOBBIN AS SHOWN. WHEN BOBBIN IS SLIGHTLY FILLED, SNIP OFF THE END OF THREAD. HOLDING THE END OF THREAD, START MACHINE. PUSH BOBBIN WINDING SPINDLE TO THE RIGHT UNTIL IT CLICKS. PLACE BOBBIN ONTO BOBBIN WINDING SPINDLE "B" WITH END OF THREAD COMING FROM THE TOP OF THE BOBBIN. THREAD THROUGH THE BOBBIN WINDER TENSION DISK "A" AND THE HOLE IN THE BOBBIN FROM THE INSIDE TO THE OUTSIDE.

GUIDE THE THREAD AROUND THE THREAD GUIDE.

#601c swf embroidery machine free#

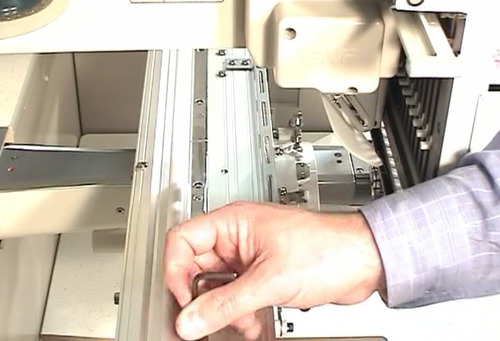

SPECIAL TOOLS REQUIRED O V1.0ģ SEWINGMACHINEDIV.20 LOCATE AND IDENTIFY THE PARTS BOBBIN WINDING TENSION DISC THREAD THREAD TAKE-UP LEVER GUIDE BOBBIN WINDING SPINDLE BOBBIN WINDER STOPPER TOP THREAD TENSION CONTROL LENGTH DIAL FACE COVER STITCH SELECTOR DIAL NEEDLETHREADER NEEDLE REVERSE LEVER EXTENSION TABLE (ACCESSORY STORAGE BOX) SPOOLPINS HANDWHEEL PRESSER FOOTLEVER LEVER FREE ARM LIGHT AND POWER SWITCH MACHINE SOCKETĤ SEWING MACHINE DtV. CLEARANCE BETWEEN NEEDLE AND HOOK (NO.2). CLEARANCE BETWEEN NEEDLE AND HOOK (NO.l). WHAT TO DO WHEN SERVICE ACCESS FACE COVER.

#601c swf embroidery machine manual#

SWF Continue to listen and develop from its customers requests.1 SERVICE MANUAL SEWING MACHINE MODEL 385, BER, 2006Ģ CONTENTS LOCATE AND identify THE PARTS.

#601c swf embroidery machine code#

With SWF machines that are World Patented capable of stitching up to 1,500spm  Dual Function Technology – where 2 different items & or designs can be stitched on 1 multi-head machine at the same time  SENS networking with bar code design transferring and reporting systems and more, Today as a premium global manufacturer, Sunstar / SWF manufacturer 1 to 56 head embroidery machines with over 150+ different models available in its range.Īll SWF machines come delivered with training and up to a 5 Year SWF Factory Warranty not forgetting our 7 Year STITCH QUALITY GUARANTEE, then you have simply the best machine that money can buy The Main SWF Range of machines offered within Europe are Single & Two-Heads, Tubular & Flat Table Standard and High Speed Multi-Heads, Tubular & High Speed Dual Function Multi-Heads and the latest KS-Series capable Stitching at 1,200spm as standard. Since its inception in 1974, SWF have been developing and manufacturing sewing and embroidery stitching machine technology from its corporate headquarters in South Korea. Today SWF continues today to encapsulate advanced machine technology in all of its SWF embroidery machines.

0 kommentar(er)

0 kommentar(er)